Springs are everywhere—inside machinery, vehicles, medical devices, electronics, and countless other products. While off-the-shelf springs work for some applications, custom springs are often the key to unlocking superior performance and long-term reliability. Here’s why investing in custom spring solutions from a trusted supplier like Penn Elkco Spring can make all the difference for your next project.

Designed for Your Specific Needs

Every product is unique, and so are its mechanical requirements. Custom springs are engineered to precise specifications, ensuring they deliver the exact force, motion, and durability your design demands. Instead of compromising with a generic part, you get a spring that’s perfectly matched to your application—improving fit, function, and overall product quality.

Enhanced Performance Under Real-World Conditions

Standard springs may not account for the unique stresses, loads, or environmental factors your product will face. A custom-designed spring can be tailored for specific operating conditions, such as high temperatures, corrosive environments, or repeated cycling. This means fewer failures, less downtime, and a better end-user experience.

Optimized Material Selection

Choosing the right material is crucial for spring performance and longevity. Custom spring suppliers like Penn Elkco Spring offer expert guidance on material selection—whether you need stainless steel for corrosion resistance, music wire for high strength, or specialty alloys for demanding applications. The right material ensures your spring maintains its properties over time, even in tough environments.

Quality Assurance and Consistency

Custom springs from a reputable manufacturer go through rigorous quality checks and testing. At Penn Elkco Spring, every spring is manufactured to exacting standards, with thorough inspection and documentation. This attention to detail ensures each spring performs as intended, batch after batch, giving you peace of mind and reducing the risk of costly recalls or repairs.

Streamlined Integration and Assembly

Custom springs are designed to fit seamlessly into your product’s assembly process. This can reduce installation time, minimize the need for adjustments, and help prevent assembly errors. The result? Increased efficiency on your production line and fewer headaches for your team.

Real-World Example: Solving a Common Challenge

Consider a manufacturer of industrial equipment struggling with premature spring failure in a high-load application. Off-the-shelf springs couldn’t handle the repeated stress, leading to frequent breakdowns. By partnering with Penn Elkco Spring for a custom solution—engineered with the right material and coil geometry—the manufacturer saw a dramatic increase in spring life and equipment uptime. This not only improved customer satisfaction but also reduced maintenance costs and warranty claims.

Why Choose Penn Elkco Spring?

With decades of experience and a commitment to quality, Penn Elkco Spring partners with manufacturers, engineers, and designers to deliver custom spring solutions that drive product performance and reliability. From initial concept to final production, their team works closely with you to ensure your springs are engineered for success.

Ready to see how custom springs can transform your product?

CONTACT PENN-ELKCO SPRING TODAY!

When it comes to mechanical design, springs are the unsung heroes—small parts that have a big impact on performance, safety, and reliability. Whether you’re building industrial machinery, medical devices, or automotive components, specifying the right custom spring is essential. Here’s a practical guide to help you get started.

When it comes to mechanical design, springs are the unsung heroes—small parts that have a big impact on performance, safety, and reliability. Whether you’re building industrial machinery, medical devices, or automotive components, specifying the right custom spring is essential. Here’s a practical guide to help you get started.

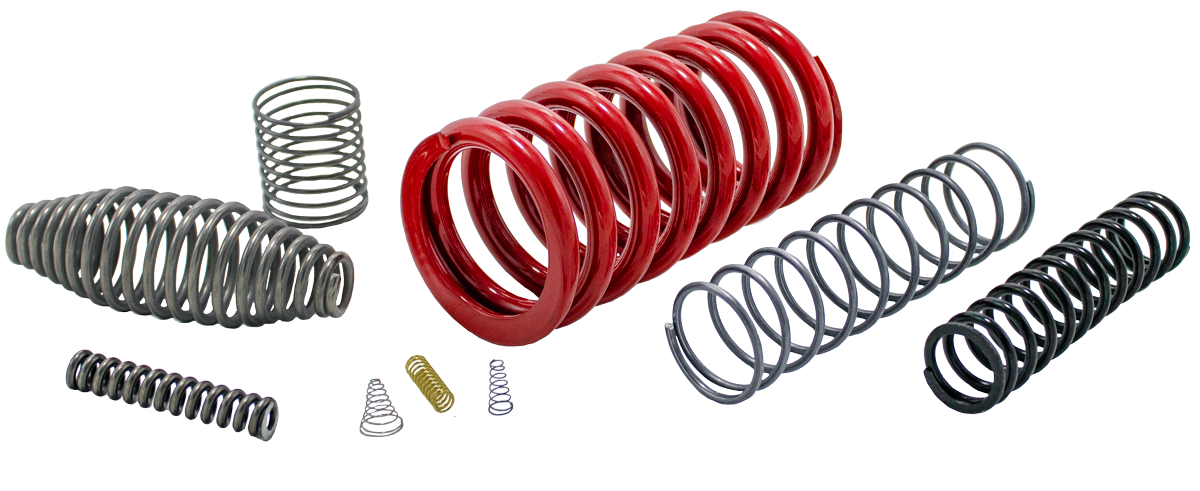

Compression Springs

Compression Springs

ISO 9001:2015 Certified •

ISO 9001:2015 Certified •